CU Boulder's Paul M. Rady Department of Mechanical Engineering is committed to providing students with an education complete with active learning. Though the pandemic has made the semester more challenging, faculty and staff have been daily innovating to make their courses as hands-on as possible while also ensuring the safety of their students. See how some of your favorite classes and facilities have committed to active learning below.

Manufacturing Processes and Systems

Taught by Janet Tsai and David Wolenski

Mohammed Jalali completes the Heat Treatment Lab in Manufacturing Processes and Systems.

In Manufacturing Processes and Systems, we focused on setting up three in-person, hands-on lab experiences: Casting, Inspection with Geometric Dimensioning and Tolerancing (GD&T), and Heat Treatment. We branded each of these in-person labs as a “Navy SEAL Mission" meaning that students are prepared and trained ahead of time with a clear mission objective to accomplish in-person, so they can easily get in and get out of the lab, completing their required tasks while minimizing their exposure. Each in-person lab was scheduled down to the minute, with individual students coordinating within their three-to-four person lab groups exactly who was going to be where and when. This requires a lot of logistics and planning, especially since our class includes students from Colorado Mesa University who use their lab in Grand Junction, coordinated by Dr. Nathan McNeill.

In addition to the three in-person labs, we also have two remote labs: Statistical Process Control (SPC) and Plastics. For the Plastics Lab, students are given a set of tasks to accomplish by examining various plastics around their homes, investigating how household plastics are created and formed and even doing some at-home tests to identify mystery plastics. To support both the in-person and at-home lab experiences, Professor Tsai got to hone her video editing skills, combining raw footage shot in the Idea Forge with still images showcasing real-world examples and specifics of measurement. Usually, the Manufacturing Processes and Systems course includes at least one department-arranged visit to a real manufacturing site. During fall 2020, we have been going on virtual tours instead, viewing manufacturing documentaries posted to YouTube from both modern and vintage manufacturing sites across the world.

Design for Community

Taught by Dan Riffell

As part of Design for Community, students are competing with the rest of the class to have their design manufactured. One of these designs is shown above.

In Design for Community, we currently have a waiting list of client projects for us to address. I treat this class like an active engineering consultancy in order to keep students engaged. Some of our projects require teams of students to engage with a client long-term, and some of the projects require that I pull one student away for a few days to complete less labor-intensive tasks. The addition of client deliverables, communication, scheduling and team organization creates active and dynamic environments for learning. Additionally, I have created internal competitions for our design coursework where students compete with the rest of the class to have their designs manufactured.

Data Analysis and Experimental Methods

Taught by Keith Regner

In Data Analysis and Experimental Methods, students still get to complete all the labs in the course. During in-person instruction, students worked individually on the labs to conform to social distancing rules. When CU Boulder went remote, we organized a checkout process to get the lab equipment in the hands of every student—more than 100—to complete the lab remotely at home.

Idea Forge Operations

Observations by Shirley Chessman

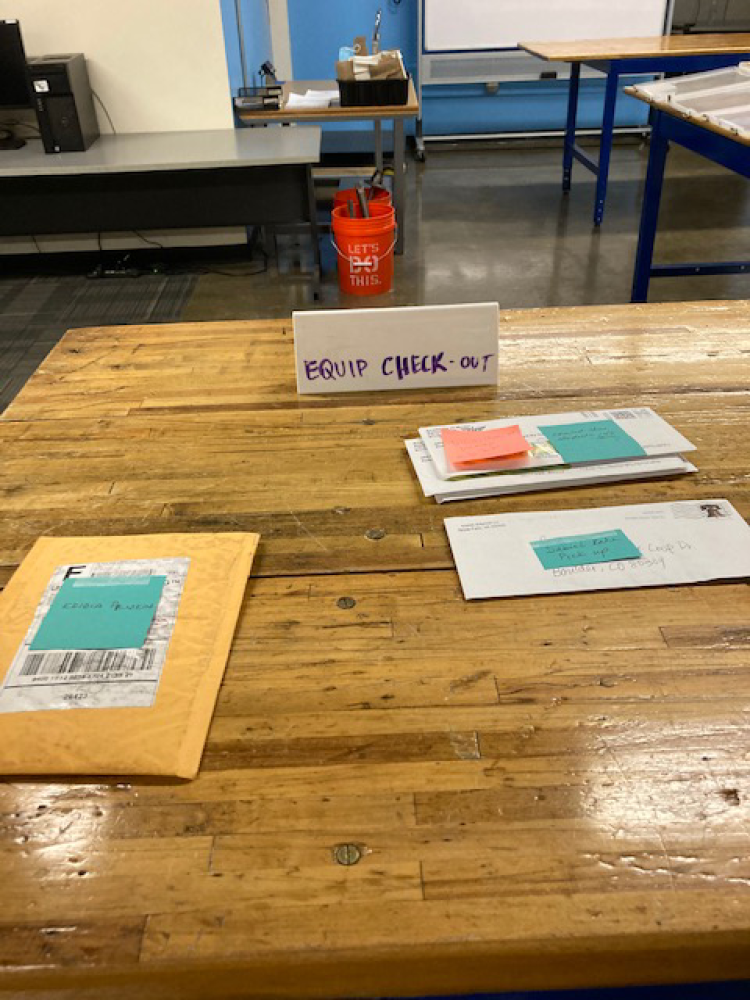

Idea Forge Mechanical Lab Engineer Shirley Chessman's equipment check-out station in the Idea Forge.

At the beginning of the semester, we supported faculty, ordering and distributing document cameras and any test equipment needed for remote/recorded lab demonstrations and helping to coordinate lab space and equipment for a small number of in-person labs.

Now, as the semester has progressed, things are more student focused. Students schedule Zoom meetings and we discuss their need and purpose. I will use my webcam to show them different pieces of equipment. The items will then get checked out to the student and left in the DIDL for contactless pick-up. A similar virtual process has been developed for 3D printing, woodworking, and machine shop fabrication. Students set up virtual consultation meetings with the shop engineers to have drawings and specifications clarified. These consultation meetings provide an opportunity for students to practice technical communication skills as well as receive design guidance. After completing the consultation meeting, necessary design changes are made, then the student will submit a work order. The shop engineers fabricate the parts and also leave them for contactless pick-up.

I have made a few trips to FedEx to ship some pieces of equipment to students who are not campus adjacent. Some Senior Design teams are beginning to order parts or their clients are shipping things for their projects. I have been receiving these and either storing them or setting them out for pick-up. Lately, I’ve been helping set up an outdoor classroom for Daniel Knight’s Project Based Learning in Rural Schools and some graduate students who needed equipment to teach classes and have been working with Idea Forge staff as we slowly start allowing student teams to use Idea Forge facilities for meetings.

Senior Design - Industry-Sponsored & Engineering for Social Innovation Sections

Taught by Daria Kotys-Schwartz, Dan Riffell, Julie Steinbrenner

Despite the COVID-19 pandemic, ME Senior Design is still providing students with a project-based, transitional engineering experience. With 27 industry-sponsored projects and two competition teams in the industry-sponsored section and five unique projects in the Engineering for Social Innovation (ESI) section, students are already well underway with the design and early prototyping of their projects. Students are meeting teammates, directors and clients remotely, with in-person, masked and socially-distanced meetings arising as local health orders permit.

Teaching design in a remote setting presents many challenges, including allowing students to physically prototype with their teammates despite being distant from one another. Therefore, we have modified some of our typical activities to be more representative of engineering with a remote team. For example, we added new, relevant learning objectives to the marshmallow/spaghetti tower build that has been used as a team-building exercise in the past; this year, the activity focused on designing with a remote team, including communication, strategy and execution of a design while physically separated. It also inadvertently produced many marshmallow Ralphies, the CU Boulder mascot.

Projects will continue to include design, build, assembly and testing of physical prototypes though COVID-19 constraints require new processes. There is an increased emphasis on design for manufacturability and design communication, as the fabrication facilities on campus move to order intake systems where staff produce parts for students to reduce the risk of facilities closing. Much like spring 2020, teams will assemble and test hardware on-campus and off-campus, according to resource needs. We are getting creative to address the challenges related to our projects and preparing the next generation of engineers who will launch into their careers in unprecedented times.