TissueForm: Next Generation Biomaterials

Company Brief

TissueForm supplies natural replacement biomaterials to the next generation of implantable medical devices to positively impact patients suffering from tissue loss due to disease, damage, or aging. The biomedical technology company is producing tissue-based, bio-inspired biomaterials to address clinical problems in industries including regenerative medicine and 3D-bioprinting. Their core competency is in the design, development, bioengineering and fabrication of acellular biomaterials composed of natural and cross-linkable tissue components, which are easily delivered and formed to closely mimic natural tissues, and which demonstrate transformative structural, mechanical, cellular response, and healing behavior in the body. TissueForm was born out of the Neu Soft Tissue Bioengineering Lab at CU Boulder. Scientific and business development is led by Jeanne Barthold (PhD) and Corey Neu (PhD) and advised by a strong network of business, legal, regulatory, and industry advisors.

Technology

Using bio-inspired design principles, and advanced tools of biotechnology, TissueForm has developed a platform technology for the biomimicry of body tissues to repair areas of significant tissue loss or injury. The catalogue of products in development include our beachhead dermal filler material (NatruDerme) and future follow on materials for 3D bioprinting (NatruGel), and articular cartilage repair (NatruLage). The platform material technology is characterized by a unique combination of acellular particles crosslinked to natural biomolecules that provides tissue-specific properties and performance, while also allowing for easy forming and integration upon delivery to the patient, and low-cost fabrication. The acellular materials maintain tissue-specific growth factors, encouraging migration and homing of the patient’s own (autologous) stem and primary cells from the surrounding tissue into the acellular material to promote rapid healing and durable repair. Additionally, the complex tissue scaffold provided by NatruDerme, etc. supports a stable and long-lasting native tissue matrix resistant to degrading enzymes that otherwise limit implant longevity.

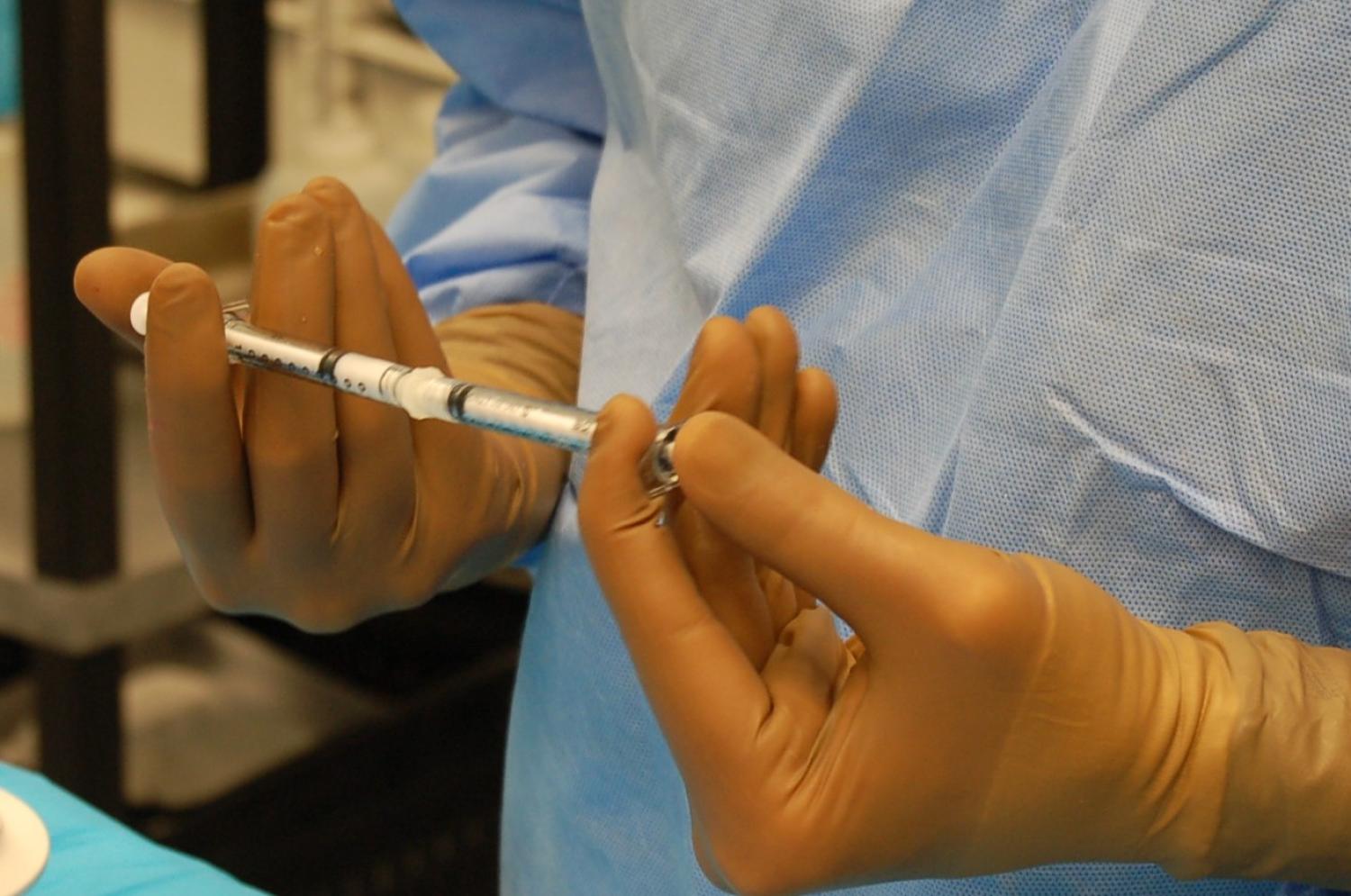

MVP Prototype in use (right): Two-part biomaterial with custom syringe luer lock mixer to ensure thorough mixing and straightforward application through a needle.

Advantages

- The primary advantages of TissueForm's first product, NatruDerme, against competitors include:

- Recreating native tissue architecture and structure

- Matching native tissue mechanical properties

- Achieving positive cellular responses to the material and demonstrates healing

- Enabling long shelf life with acellular, lyophilized form while eliminating the need for a cold supply chain.

- Long lasting repair, resistant to naturally occurring degrading enzymes

- The acellular, biocompatible, and regenerative matrix of NatruDerme supports natural tissue growth for a natural, long lasting, and scar-free tissue repair.

Future Applications

- Platform technology has been shown in R&D to provide a structural matrix and necessary signaling molecules to promote articular cartilage defect repair.

- TissueForm’s novel material has been adapted to enable high precision 3D bioprinting with our realistic bioink, composed of complex ECM and natural hydrogel, which crosslink post printing.

What's Next?

TissueForm is focusing on the pathway to commercialize its first product, NatruDerme. TissueForm is looking to raise seed financing alongside non-dilutive federal and state grants to enable critical FDA-pathway defined manufacturing and pre-clinical studies.

Nicole Forsberg: nicole.forsberg@colorado.edu

The Newsroom

For marketing and communication inquiries or news tips, contact Daniel Leonard, senior marketing and communications specialist for Venture Partners at CU Boulder.

For media inquiries, please visit colorado.edu/news/formedia.