Planning for the Next Boom

Why the Time Might Be Right for Oil Shale

The factors that have incited previous booms in Shale Country are falling into place today. During the 2008 legislative session, high energy prices throughout the United States turned a spotlight on the hazards of depending on overseas energy suppliers. As calls to develop domestic energy resources increased in volume and chants of “drill, baby, drill” rang out at political rallies, then-Senator Ken Salazar (now Secretary Salazar) and his allies were unable to extend the moratorium on commercial leasing regulations for another year, and it expired at the end of September.

Secretary Salazar has consistently maintained that he supports the development of oil shale if it can be done in a way that minimizes negative impacts on the human and ecological communities of Shale Country. Several energy companies – notably RD&D lease holders Shell, Chevron, and AMSO – echo this sentiment that oil shale development must be “done right” or not done at all. But with a bout of soaring energy prices fresh in their memories and geopolitical anxieties rippling through global energy supply lines – lines increasingly stretched thin by instability in the oil rich Middle East and rising demand from developing nations like China and India – a growing portion of Americans believe that the United States must move faster to develop more of the energy sources within its borders, including offshore oil deposits deep under the ocean floor and the oil shale buried under the Western Slope of the Rocky Mountains.

A national recession, rising oil prices, instability in the Middle East, and encouragement from the Bush Administration created a sense in Shale Country that another boom might be on the horizon. The cycle felt familiar but this time, having learned from the previous busts, the federal government, local communities, state regulators and company officials set forth with a considerable amount more planning than in previous booms-and-busts. Although, as we all know, no amount of planning can prepare ourselves for all the risks and intangibles that the future holds.

Domestic Benefits

Advocates for tapping more of our domestic energy sources persuasively point to a variety of national security and economic benefits that would accompany such development. Many of the world’s richest oil and gas supplies lie in places wracked by perpetual political instability or controlled by governments that view the US in less-than-friendly terms. Reliance on these unreliable suppliers poses a threat to America’s national security that can be reduced by increasing production of domestic oil and gas resources.

Developing our domestic energy resources is not a panacea. In this globalized century, it is no longer credible to argue that the United States can drill its way out of this energy crisis. It is even time to reassess the late-twentieth-century dream of American energy independence in a fossil-fuel-driven world economy. Nevertheless, the development of major domestic energy sources like oil shale would be a significant step toward gaining greater national control over our energy supply. Oil shale has the potential to shift the center of gravity in the US petroleum supply away from the Persian Gulf and to the Americas, thus freeing the nation from our reliance on unfriendly oil producers overseas.

What’s more, such a shift would curtail the enormous transfer of wealth that results from US dependence on foreign oil. If more oil were produced in the United States, Americans would direct their dollars into energy industry jobs closer to home rather than send huge amounts of capital to overseas oil suppliers.

Why Now?

The history of efforts to develop an oil shale industry on the Western Slope is not encouraging, but oil shale advocates point to several changes since the last bust that make the industry finally viable in the twenty-first century. First and foremost, global oil production has leveled off and may have reached its peak. In contrast to the 1970s, when oil prices were artificially driven up by the OPEC oil embargo, escalating energy prices today reflect increasing global demand for a truly limited resource. The anomalous oil price whiplash of 2008 not withstanding, the relatively stable price trajectory created by this tightening market – and the steady revenue streams an upward trajectory will create – provide an economic incentive for development and make it easier for companies to invest in new resources and new technologies without fearing sudden market fluctuations that might kill new development. Oil shale is near the top of the list of promising new fossil fuel resources to invest in because it is richer in energy than other remaining unconventional resources.

The energy companies at work in Shale Country today believe that, even if crude oil prices level out, oil shale’s moment may finally be at hand. As Shell spokesman Tracy Boyd recently put it, “Regardless of where oil prices are, we think the opportunity is great and the benefit is great. We plan to continue our slow and methodical approach and stay the course.” Although a commercial industry is still a decade or two in the future, the new generation of in situ technology that Shell and its counterparts in Shale Country are methodically investing in has the potential to make oil shale development economically and environmentally viable. And at a moment when national security concerns are converging with economic anxieties in a troubling pattern, the prospect – and potential ramifications – of developing this massive domestic energy resource staggers the mind.1

The 2005 Energy Policy Act

The Third Time Is the Charm (Right?)

Skyrocketing gas prices have indicated previous oil shale booms and today, a volatile international oil market, a recent bout of sticker shock at the gas pump, and growing recognition that dwindling oil reserves will struggle to meet the world’s future energy demands have combined to once again pique interest in the rock that burns. And once again, the federal government is stimulating that interest. As oil reserves dwindle and gas prices rise politicians, scientists and concerned citizens are looking for an answer to the 21st Century energy issue. Similar to wind, solar and nuclear energy, oil shale has its advocates as a fuel to provide jobs and meet the energy demands of the 21st Century.

In 2003, as oil prices began to climb, the Bureau of Land Management (BLM) initiated an oil shale development program in conjunction with President George W. Bush’s National Energy Policy, soliciting applications for research, development, and demonstration (RD&D) leases. The 2005 Energy Policy Act (PL 109-58), section 369 (PDF), further encouraged the development of oil shale resources as part of a comprehensive approach to meeting the growing national energy demand by requiring the Department of the Interior to issue commercial oil shale leases by 2008. Research in Shale Country proceeds along multiple tracks as companies use federal, state and private lands to unlock the “secret in the rocks.” Oil shale leases are given for federal RD&D, federal and state commercial, and on private property (although there is no actual “lease” on private lands). Each rout has its own regulations and statues and each has its own benefits and drawbacks for oil companies and land owners.

RD&D Leases

Testing a New Generation of Technology

The federal government controls most of the land in Shale Country and thus any calls for action by the federal government receive the most response from energy companies. In response to the BLM’s oil shale development program, 20 companies applied for new oil shale leases in the Green River Formation. Ultimately, the BLM selected 6 proposals – 5 in Colorado (3 separate bids by Shell and one each from Chevron and EGL Resources, the latter of which has since been renamed American Shale Oil) and one in Utah (the Oil Shale Exploration Company) – as worthy of continued consideration.

The federal leasing process requires that energy companies comply with an array of environmental and economic regulations before the companies are allowed to proceed to development. The RD&D—Research, Development and Demonstration—process includes multiple rounds of applications and comment periods, both by the government and the public. One step in the process is the Programmatic Environmental Impact Statement (PEIS) issued by the BLM. The PEIS takes into account the full range of technology available and the potential impact that the oil shale industry would have on land, water, and air quality in Shale Country. The BLM then offers recommendations for the amount of federal land that should be made available for leasing to the companies. The federal government in recent years has preferred the RD&D process to commercial leasing because it requires the companies to prove their process and allows for the public to comment extensively before companies begin actual extraction.

Each of the Colorado proposals identified 160-acre tracts on public land in the Piceance Basin in Rio Blanco County southwest of Meeker for their RD&D operation, while the one in Utah focused on a parcel in Uintah County (see map). Each company also nominated a contiguous area of 4960 acres to be reserved for preferential commercial leasing options in the future, should their research pan out. The lease period is 10 years with a renewal option of 5 more. In 2007, once the BLM completed the Environmental Analysis required by NEPA and found that the proposed RD&D operations would produce “no significant impact,” the agency officially issued leases that allowed the companies to begin work. 2

Commercial Leasing

Running parallel but independent of the RD&D program, the commercial leasing process stipulated by the 2005 Energy Policy Act is also underway. The act required the BLM to prepare a programmatic environmental impact statement (PEIS) for “the most geologically prospective lands” (meaning the land above the richest oil shale deposits) in the Green River Basin within 18 months of the bill’s August 2005 passage. The act then mandated that commercial leasing commence roughly a year after the PEIS was completed. That was the original plan, anyway. Although the timeline for development is shorter than the RD&D program, the commercial leasing process has not proceeded as far as its counterpart, mainly due to opposition from key Colorado lawmakers.

Slow Start on the Fast Track

In 2006 the BLM began the rulemaking process for commercial leasing, and in December 2007 it released a draft version of the PEIS for public comment, finalizing it nearly a year later in September 2008. Already well behind schedule with the PEIS, the BLM’s commercial leasing program has been further slowed down by the consistent efforts of three Colorado lawmakers: Senator Mark Udall (a representative prior to 2009), Representative John Salazar, and his brother, Secretary of the Interior Ken Salazar (a senator prior to 2009). These three, supported by allies at the federal and state level including Colorado Governor Bill Ritter, organized a legislative moratorium that delayed the BLM from finalizing the regulations for commercial leasing until the final week of the Bush Administration in January 2009.

This cautious coalition maintains that they are not categorically opposed to oil shale development, but that they want to ensure that any development proceeds in the most socially, economically, and environmentally responsible manner possible. As Secretary Salazar has explained, rather than the rush to development that they feel is at the heart of the 2005 Energy Policy Act’s oil shale section, a “judicious approach to oil shale development will help Western Slope communities avoid any unfortunate bust that comes from an unchecked boom on commercial leasing. . . . as happened in the 1980s, when we went through our last bout of oil shale fever – of which many of the communities of Western Colorado are still feeling the effects of today.”

The likeminded legislators have been assisted by a coalition of environmental groups who filed multiple suits aimed at preventing the commercial leasing regulations from taking effect. The suits have put the status of commercial leasing and the BLM’s land use plans for Shale Country into limbo while they slowly work their way through the courts. Meanwhile, the go-slow position gained new prominence when President Obama appointed Ken Salazar as Secretary of the Interior. A little more than a month after he was confirmed by the senate, and just days after he told a group of Western governors that oil shale was still “on the table,” in February 2009 Secretary Salazar announced that he was withdrawing the recently solicited second round of RD&D lease offerings. In their place, he has directed the BLM to offer a new round of RD&D leases that rectify what he considered the flaws of the earlier regulations. 3

Private Enterprises

Apart from the federal RD&D program, several energy companies, including independent ventures like Red Leaf Resources in Utah and energy industry heavyweights like ExxonMobil, are also working privately on oil shale processes with an eye toward obtaining commercial leases when the time comes.

Utah-based Red Leaf is developing a hybrid technology it calls the EcoShale Process, which combines elements of conventional mine and retort methods with in situ techniques. Exxon, in its return to Shale Country, is developing an in situ technology it calls the Electrofrac process, which it may test on private property at the company’s defunct Colony Project site near Parachute, Colorado. Exxon plans to fracture the target oil shale formation and fill the cracks with an electrically conductive material that will serve as a heater. As the heated kerogen separates from the rocks, the resultant oil and gas will be pumped to the surface. Exxon believes this process will require less drilling than individual heaters and thus leave a smaller footprint on the landscape.

Other major energy industry players such as Schlumberger, the world’s largest oilfield services company, are positioning themselves to take advantage if an oil shale industry does get off the ground. In early 2008, the company put 375 acres of private ranchland near DeBeque, Colorado, under contract. Although the site will primarily be used as a base of operations to serve the current oil and gas operations in the Piceance Basin, the Paris-based company also has an eye toward oil shale. Around the same time they purchased the land, Schlumberger also acquired an in situ technology that uses radio wave technology to separate the kerogen from the rock underground. Additionally, Schlumberger is already dipping its toes into the shale deposits through a venture with AMSO to help characterize the resource on their RD&D lease. 4

The Technology: Two Methods of Extraction

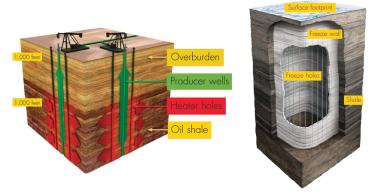

Of the 6 RD&D leases awarded, the one in Utah proposed a conventional surface mine and retort method at an existing mine site, while the 5 in Colorado were for in situ operations. The conventional mine and retort method (sometimes called ex situ) relies on digging the oil-bearing shale out of the ground, crushing it into small pieces, and separating the oil-like kerogens from the rock by heating it in a centrally located piece of machinery called a retort. In situ refers to a method of recovering the oil contained in shale rock by heating it in place underground and using wells to extract it.

Essentially, the in situ process mimics the natural geologic process that produced conventional deposits of oil and gas, the process that would eventually take place in Shale Country over millennia. Although the details vary substantially between operators, the general in situ procedure is to artificially heat the rock within shale layers – the richest of which are called the “mahogany zone” because of the oily rocks’ rich brown color – over a period as long as several years until liquefied oil is ready to be pumped to the surface through wells.

Despite significant technical obstacles and environmental questions still to overcome, in situ recovery appears to be the most viable approach to oil shale under the current economic and environmental regimes, offering lower recovery costs and a more limited footprint on the landscape compared to the conventional mining methods. The idea is not new, but the in situ techniques being developed at public RD&D leases and on private tracts today represent an original and innovative phase of thought and technology. A quick survey of some of these processes shows the variety of thought encompassed under the broad notion of in situ extraction.

The Players

The Leaseholders

Of the 3 companies granted RD&D leases to develop in situ methods, Shell has garnered the most attention so far with its In situ Conversion Process (ICP), which it has been developing since the early 1980s at the company’s privately owned Mahogany Research Project site in the Piceance Basin. The process relies on electric heaters inserted down drilled holes to the depth of the targeted layer of shale, where they will gradually heat the rich rock formation over several years to a temperature of between 650 and 700 degrees Fahrenheit. The heat will fracture the shale rocks and convert the kerogen bound within them into oil and gas that can be pumped to the surface with conventional production wells. To prevent the mobilized oil and gas from contaminating groundwater, Shell is testing the viability of an underground freeze wall – a closed system of refrigeration pipes drilled 8 feet apart and 1800 feet down – designed to create an impermeable frozen barrier surrounding the heated zone.

On a lease site just to the south of the Shell claims, American Shale Oil (AMSO, formerly EGL Resources) is pursuing a similar concept, which they refer to as the Conduction, Convection, Reflux (CCR) Process. In the CCR process, rocks in the target zone will be heated by an L-shaped well drilled horizontally into the area. As the organic matter within the rocks boils, it will break the rocks apart and free the oil and gas to be collected and pumped to the surface by a conventional production well. AMSO believes that by heating the rock more quickly than Shell plans to – 3 to 12 months as opposed to several years – the CCR process will consume less energy and require fewer wells, thus minimizing the amount of land disturbed on the surface and reducing the amount of water needed to less than one barrel per barrel of oil produced. To protect groundwater, the company plans to target deeper layers of oil shale below the basin’s aquifer (rather than the mahogany zone closer to the surface), leaving in place layers of rock above the target zone that will serve as a natural geologic barrier against groundwater contamination.

In contrast to these steady heating approaches being developed by Shell and AMSO, Chevron is hoping to use chemistry to produce oil from the rock. The company has teamed up with experts from Los Alamos National Laboratory and the University of Utah to explore a variety of methods, but the leading candidate is a process they call CRUSH (a loose acronym for Chevron’s Technology for the Recovery and Upgrading of Oil from Shale), which intends to rubblize rich swaths of shale with precisely controlled chemical explosions before injecting a solvent (such as heated carbon dioxide) to separate the kerogen from the shale. Once dissolved by the chemical reaction, the energy-rich hydrocarbons in the kerogen could be pumped out using a conventional production well. Chevron believes that the CRUSH process will require significantly less energy and water than other in situ methods and will sequester much of the carbon dioxide underground, thus reducing its environmental impact and making it more economical even at lower oil prices. In fact, the company predicts that its method will consume less water than the quantity of groundwater pumped out of the target zone (a routine procedure in energy fields), leading the company to claim that it will be a net “producer” of water. To protect groundwater quality, much like AMSO, Chevron plans to target shale beds capped by impermeable geological formations that can permanently prevent groundwater from seeping through the contaminated rubble.

With so much still to demonstrate on these RD&D projects, none of these 3 in situ lessees expect to conclude testing or make any decisions about the next stages of production for several more years. Meanwhile, at the White River Mine RD&D lease site in Utah, the Oil Shale Exploration Company (OSEC) claims that its conventional surface mining and retort process, based on technology developed in the 1950s and used in Brazil for nearly two decades, is ready to produce 4000 barrels a day from deposits that lie closer to the surface than those in the Piceance. However, this more established form of resource extraction also carries a host of established environmental impacts – from carbon dioxide released during the retortion process to the difficulty of reclaiming mined sites and the potential for phpacid mine drainage needing perpetual management – that cast it in a less attractive light for many policymakers than the promise, albeit unproven, held out by in situ processes. 5

New Technology, Old Questions

Although in situ technology holds out the hope of producing oil shale with a lighter environmental touch than the conventional method, the companies working on these new processes today face numerous challenges and uncertainties. The viability of in situ extraction hinges not only on perfecting the technology and chemistry but also on significant questions about how they will impact local communities, the land, air quality, and water resources in Shale Country. Will the next generation of operators work with local communities in ways that create a sustainable postive impact on society and the economy? Can they tread lightly enough on the land to preserve the integrity of native ecosystems? What will their presence mean for other uses of the land, such as ranching or recreation? In the arid West, how much water will these processes require? Where will it come from? Will the proposed protections against groundwater contamination be successful? Can operations be powered in a way that safeguards the area’s near-pristine air quality?

These questions are not new. The conventional mine and retort operators faced many of the same questions – and too often failed to provide satisfactory responses – during the last boom cycle. But the energy companies developing the next generation of technology in Shale Country today will need to come up with novel answers if they are going to live up to their pledges to “get it right this time.”

Fair Returns

Where Oil Shale Revenues Go

Royalty Rate Debate

One of the most contentious aspects of the commercial leasing rulemaking process, and one that Secretary Salazar identified as a major problem with the regulations he withdrew, is the royalty rate, the percentage that companies pay for extracting public resources. In the now-withdrawn regulations, the BLM set the royalty rate at 5% for the first 5 years and then increasing 1% per year until it reached 12.5%. Ken Salazar (speaking as a senator when the rates were first announced in November 2008) called them a “pittance” compared to the 12.5% to 18.8% that the government typically collects on domestic oil production.

The royalty rate can be a powerful tool to encourage – or discourage – development. Oil shale advocates contend that a lower royalty rate will help offset the high startup costs and risks associated with developing a new industry and will go a long way toward encouraging companies to take the plunge. But policymakers like Udall and the Salazars are concerned that setting the rate too low will shortchange taxpayers if the industry takes off. Some would like to avoid setting the rate “prematurely” before the technology is proven and other key questions about its impact on the environment and local communities have been answered, but companies operating in Shale Country are hesitant to large long-term investments without some certainty in the regulatory framework they will be operating under.6

Although no one can say for certain whether oil shale will one day be produced profitably and the royalty rate companies will pay is still a subject of debate, laws are already in place at the state and federal level to distribute any money generated for the public by the future industry.

Roughly half (the exact percentage has fluctuated by a few points over the past few years) of the money that energy companies pay to the federal government as royalties will be returned to the states in which the development occurred. Each state has a different method of distributing these funds. In Colorado, where the richness of the Piceance Basin deposits mean that a successful oil shale industry could translate into enormous amounts of money washing through the state government, this money is funneled into the state’s Oil Shale Trust Fund. State legislators created the fund in 1974 as a mechanism to distribute 100% of the state’s share of the federal Mineral Leasing Act royalty monies derived from oil shale lands back to local governments for mitigation of the impact of oil shale development on the communities it directly affects.

Shale Country states will also receive money from individual companies in the form of severance taxes, which are charged to energy and mining companies in an effort to recapture part of the public wealth lost when nonrenewable resources are extracted and sold for private profit. In Colorado, which currently charges a lower severance tax than most of its Rocky Mountain neighbors, by law this money must be used for public purposes related to mineral development, for water projects, or help for local governments to offset the impacts of energy development. The state distributes the revenues evenly into two channels: the Severance Tax Trust Fund, which funds statewide mitigation and resource stewardship projects through grants and loans, and the Local Government Severance Tax Fund administered by the Department of Local Affairs (DOLA), which directs 30% (up from 15% in 2007) of all state severance tax money to local governments to address the social and economic impacts of mineral production. Each fund has its own mind-boggling allocation formula and is the source of much political wrangling at the statehouse.

If a new oil shale boom does come to Colorado’s Western Slope, these financial mechanisms and their counterparts in Utah and Wyoming will direct a significant portion of money back to the affected communities. Whether it – or any – amount of money will be sufficient to ease the strain of the next boom remains to be seen.

Notes:

1 For the companies’ expressed commitment to conducting the next round of oil shale development the “right way,” with careful attention to environmental and community impacts, see statements on the Shell and AMSO websites. We have also heard personal assurances that oil shale must be “done right” this time from Chevron officials such as Robert Lestz and Sean Norris and Shell officials Tracy Boyd and Gale Norton. The arguments for the development of oil shale are repeated by many proponents, but the most comprehensive case for oil shale was made by the Task Force for Unconventional Fuels in America’s Strategic Unconventional Fuels vol. 1-3 (Sept 2007), available for download here. See also Harry R. Johnson, Peter M. Crawford, and James W. Bunger for the Deputy Assistant Secretary for Petroleum Reserves, Office of Naval Petroleum and Oil Shale Reserves, Strategic Significance of America’s Oil Shale Resource vol. 1-2 (March 2004), available for download here; James W. Bunger, Peter M. Crawford, Harry R. Johnson, “Is Oil Shale America’s Answer to Peak-Oil Challenge?” Oil and Gas Journal (9 Aug. 2004): 16-24 (PDF); and others. Tracy Boyd of Shell quoted in Jerd Smith, “Shell Stakes Claim on Yampa River,” Rocky Mountain News, 8 January 2009.

2 BLM, Final PEIS, 1.9-10; BLM, “Interior Department Issues Oil Shale Research, Development and Demonstration Leases for Public Lands in Colorado” (15 December 2006); BLM, “Interior Department Issues Oil Shale Research, Development and Demonstration Lease for Public Lands in Utah” (28 June 2007). Originally, the BLM announced 8 bids worthy of further consideration (“BLM Announces Results of Review of Oil Shale Research Nominations” [17 January 2006]), but this number was ultimately paired down to 6. Of these 6, the 5 in Colorado received their leases on January 1, 2007, and the one in Utah received its go-ahead on July 1, 2007. The 160-acre size of their initial RD&D lease tracts is minimal in the overall scope of potential oil shale developments, but, for perspective, these small parcels are the same size at the quarter-sections originally surveyed and allotted to Western homesteaders by the General Land Office.

3 “Senator Salazar Lauds Oil Shale Limitations in Omnibus Bill,” press release, 17 December 2007; HR 2764, section 433; Thomas Burr, “Salazar: Oil Shale Development on the Table,” Salt Lake City Tribune, 22 February 2009; “Secretary Salazar to Offer a New Round of Oil Shale Research, Development and Demonstration Leases,” Department of Interior news release, 25 February 2009.

4 Peter M. Crawford and Emily Knaus, Secure Fuels from Domestic Resources (Washington DC: US Department of Energy, June 2007), 28-9 (PDF); Bobby Magill, “Many Methods, One Basic Idea Shape New Oil-Shale Technology,” Grand Junction Daily Sentinel, 30 April 2007; Information about Red Leaf and their proprietary oil shale technology, EcoShale, can be found at the company’s website; Andy Vuong, “Schlumberger Buying Land for Oil Field Services,” Denver Post, 22 February 2008; “Raytheon Technology Tapped by Schlumberger to Extract Oil from Shale,” Ratheon press release, 23 January 2008; Phillip Yates, “Oil Shale Remains in the Crosshairs,” Glenwood Springs (CO) Post Independent, 14 December 2008.

5 Shell: Royal Dutch Shell, “Welcome to the Mahogany Research Project”; BLM, Environmental Assessment: Shell – CO-110-2006-117-EA (2006), 5-9; Gary Harmon, “Shell Wants to Test Oil Shale Technology in Tiny Mideast Nation,” Grand Junction Daily Sentinel, 11 Aug. 2008. AMSO: American Shale Oil, “Our Plan”; BLM, Environmental Assessment: EGL Resources – CO-110-2006-118-EA (2006), 5-10. Chevron: BLM, Environmental Assessment: Chevron Oil Shale Research, Development, and Demonstration – CO-110-2006-120-EA (2006), 5-10; Dennis Webb, “Chevron Studying Chemistry to Develop Oil Shale Underground: Plant 10 Years Out,” Grand Junction Daily Sentinel, 7 Aug. 2008. For specific information on Chevron, we have also relied on a presentation by Robert Lestz, Oil Shale Technology Manager at Chevron, on the in situ process his team is developing (23 October 2007). OSEC: Oil Shale Exploration Company website; Associated Press, “Utah Company Says Oil Shale Technology Is Ready to Go,” Glenwood Springs Post Independent, 18 June 2008. General: In addition to company-specific resources, overviews of the processes being explored throughout the industry can be found in Peter M. Crawford and Emily Knaus, Secure Fuels from Domestic Resources (Washington DC: US Department of Energy, June 2007)( PDF); Bobby Magill, “Many Methods, One Basic Idea Shape New Oil-Shale Technology,” Grand Junction Daily Sentinel, 30 April 2007; Joe Hanel, “Big Oil Casts Shadow over Colorado’s Water Future,” Durango Herald, 6 January 2008; Bartis, Oil Shale Development in the United States, 11-23; BLM, Final PEIS, “Appendix A,” A.21-30.

6 BLM, “Oil Shale Management – General; Final Rules” (18 November 2008) (PDF); Mark Jaffe, “Oil-Shale Royalties Strike Rich Vein of Debate,” Denver Post, 18 November 2008; Mark Jaffe, “Salazar Halts Oil Shale Leases,” Denver Post, 26 February 2009; Phillip Yates, “Oil Shale Remains in the Crosshairs,” Glenwood Springs (CO) Post Independent, 14 December 2008; “Secretary Salazar to Offer a New Round of Oil Shale Research, Development and Demonstration Leases,” Department of Interior news release, 25 February 2009.